Dimensions of a large pizza box, seemingly mundane, hold secrets of surprising complexity. From the precise measurements of length, width, and height, to the intricate designs that ensure structural integrity, the journey into the world of pizza box engineering is far from simple. The quest to understand the optimal balance between box size, pizza size, and customer satisfaction leads us down a rabbit hole of fascinating calculations and design choices.

How much pizza fits, how easily it can be carried, and even the environmental impact of the materials all play a crucial role.

This exploration delves into the various factors influencing the dimensions of a large pizza box, examining the interplay between manufacturing processes, customer experience, and environmental concerns. Understanding these factors will shed light on the seemingly simple box that accompanies our beloved slices of pizza.

Box Dimensions and Design

Large pizza boxes are meticulously designed to protect and present the delicious food within. Understanding their dimensions and construction is key to appreciating the engineering behind this seemingly simple packaging. The specific dimensions, materials, and design features directly impact the box’s ability to maintain its shape, accommodate the pizza, and ensure safe handling.Common dimensions are crucial for efficient transport and storage.

The structure of the box, including flaps, seams, and reinforcements, plays a vital role in preventing damage during handling and ensuring the pizza arrives in perfect condition. The materials used for construction directly influence the box’s durability, environmental impact, and overall cost.

The dimensions of a large pizza box, typically, are about 16 inches long, 12 inches wide, and 2 inches deep. Such measurements are important for determining the carrying capacity and storage efficiency. Considering these factors, exploring opportunities in commercial real estate fort mcmurray commercial real estate fort mcmurray might require a similar level of careful consideration for space allocation, ultimately affecting the practical considerations for managing the required storage space.

The large pizza box, despite its apparent simplicity, offers a useful analogy for understanding these crucial elements of effective spatial planning.

Typical Large Pizza Box Dimensions

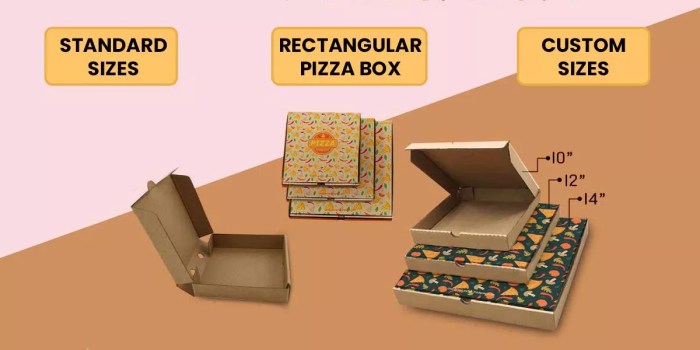

The dimensions of a large pizza box are not universally standardized, but they typically fall within a range. Variations exist based on the specific pizza size and manufacturer.

- Length: A common length for a large pizza box ranges from 16 to 18 inches (40.64 to 45.72 centimeters). This length accounts for the pizza’s diameter and allows for adequate overhang.

- Width: The typical width of a large pizza box ranges from 12 to 14 inches (30.48 to 35.56 centimeters). This dimension supports the pizza’s width and provides stability.

- Height: The height of a large pizza box usually ranges from 2 to 3 inches (5.08 to 7.62 centimeters). This height accommodates the pizza’s thickness and toppings without making the box excessively bulky.

Materials Used for Construction

The material used in large pizza boxes significantly influences their strength and durability.

- Cardboard Types: Corrugated cardboard is the standard material for large pizza boxes. Different grades of corrugated cardboard exist, influencing the box’s strength. The type of cardboard used impacts the box’s ability to withstand weight and prevent crushing.

- Thickness: The thickness of the corrugated cardboard plays a critical role in the box’s strength. Thicker cardboard provides better protection against damage and can handle heavier pizzas. This directly correlates to the pizza’s weight and the box’s ability to support it.

Design Elements for Structural Integrity

The design features of the box significantly contribute to its structural integrity.

- Flaps: The overlapping flaps are crucial for securing the box. Properly designed flaps provide a strong seal and ensure the box remains closed during transport. This prevents the pizza from shifting or falling out.

- Seams: Strong seams are essential for maintaining the box’s structural integrity. Seams reinforce the connection between the cardboard panels and contribute to the box’s overall strength. They must be robust enough to withstand the stresses from stacking and handling.

- Reinforcements: Additional reinforcements, such as extra layers of cardboard or adhesive tape, are often incorporated in critical areas to enhance the box’s structural integrity. These are especially important in areas prone to bending or crushing. They prevent the box from tearing or collapsing during handling.

Large Pizza Box Sizes and Dimensions

This table presents different large pizza box sizes and their corresponding dimensions, along with an estimated volume.

| Box Size | Length (inches) | Width (inches) | Height (inches) | Estimated Volume (cubic inches) |

|---|---|---|---|---|

| Large 1 | 17 | 13 | 2.5 | 552.5 |

| Large 2 | 18 | 14 | 3 | 756 |

| Large 3 | 16 | 12 | 2 | 384 |

Volume and Capacity

Understanding the volume of a pizza box is crucial for efficient packaging and maximizing the amount of pizza that can be accommodated. Accurate volume calculations also aid in material optimization and cost reduction in the pizza industry. A well-designed box maximizes pizza delivery without waste and ensures customer satisfaction with a properly contained product.

Calculating Volume

The volume of a rectangular prism (like a pizza box) is calculated by multiplying its length, width, and height. The formula is fundamental to understanding how much space a box occupies.

Volume = Length × Width × Height

Using this formula, a specific large pizza box size can be evaluated to determine its capacity. Variations in dimensions directly affect the volume, so it is critical to have precise measurements for accurate calculations.

Factors Influencing Volume

Several factors influence the volume of a pizza box, including variations in dimensions. Differences in length, width, and height, even slight ones, result in distinct volumes. Different materials and thicknesses of the box material also affect the overall volume. Thicker cardboard will lead to a larger overall volume than thinner material for the same dimensions. A box with a more complex or irregular shape will also have a different volume than a simple rectangular box.

Volume and Pizza Size Relationship

The volume of the pizza box directly correlates with the size of the pizza it can hold. A larger volume box is necessary for a larger pizza. For example, a large pizza requires a larger box volume than a medium pizza. If the box volume is too small, the pizza may be damaged during transport or may not fit completely.

Conversely, a box that is significantly larger than necessary can result in wasted materials. The goal is to optimize the box volume for the specific pizza size.

Comparison of Large Pizza Box Designs

Different large pizza box designs may vary in their overall volume, despite having the same pizza size. Variations in the design, such as the shape of the box (e.g., a slightly wider base), or features such as added compartments, can result in different volumes. Box designers must consider the volume requirements for the pizza, the desired material type, and the cost-effectiveness of the design to ensure the best results.

Volume Comparison Table

The following table illustrates the volume of various large pizza box sizes, considering different materials and thicknesses:

| Box Size (Length x Width x Height) | Material | Thickness (mm) | Calculated Volume (cm³) |

|---|---|---|---|

| 30 cm x 40 cm x 10 cm | Standard Cardboard | 2 mm | 12,000 |

| 30 cm x 40 cm x 10 cm | Reinforced Cardboard | 3 mm | 12,000 |

| 32 cm x 42 cm x 11 cm | Standard Cardboard | 2 mm | 14,784 |

This table provides a general comparison. Actual volumes may vary depending on the specific manufacturing process and the material’s density.

Pizza Size and Box Fit

Properly sizing a pizza and its box is crucial for efficient packaging and customer satisfaction. A pizza that doesn’t fit snugly in its box can lead to wasted space, potential damage to the pizza during transport, and an overall negative experience. This section details common pizza sizes, their relationship to box dimensions, and methods for ensuring a perfect fit.

Common Large Pizza Sizes

Large pizzas are typically available in standard sizes. Knowing these sizes is essential for determining if a pizza will fit comfortably in a given box. Common large pizza sizes are generally measured by diameter.

Pizza Size and Box Dimensions

The diameter of the pizza directly impacts the box dimensions needed for a snug fit. A larger pizza requires a box with correspondingly larger interior dimensions. Consider the height and width of the box, as well as the depth to accommodate the pizza’s thickness. The crucial dimensions are the interior width and length, which must be at least as large as the pizza’s diameter.

Potential Issues with Improper Fit

If a pizza is too large for the box, it might not fit properly. This can lead to the pizza being crushed or damaged during transport, causing a poor customer experience. Conversely, if the box is too large, it can lead to unnecessary packaging material, wasted space, and higher costs. Careful consideration of the pizza’s diameter and the box’s interior dimensions is essential to avoid these problems.

Determining Optimal Pizza Size for a Large Pizza Box

Several methods exist to determine the ideal pizza size for a given large pizza box. A critical step is measuring the interior dimensions of the box. The pizza’s diameter should ideally be smaller than the box’s interior width and length to allow for proper handling and prevent damage. Using templates or digital tools can aid in visualizing the pizza’s fit within the box.

Table Comparing Large Pizza Sizes and Box Dimensions

This table provides a comparison of common large pizza sizes and various large box dimensions. The aim is to highlight potential discrepancies and limitations.

| Pizza Diameter (inches) | Box Interior Width (inches) | Box Interior Length (inches) | Potential Issues |

|---|---|---|---|

| 16 | 16 | 16 | Likely to fit comfortably |

| 18 | 16 | 16 | May not fit snugly, potential for damage during transport |

| 20 | 18 | 18 | Likely to fit comfortably |

| 20 | 16 | 16 | May not fit snugly, potential for damage during transport |

| 22 | 20 | 20 | Likely to fit comfortably |

Manufacturing and Production

The manufacturing of large pizza boxes involves a precise sequence of steps to ensure consistent dimensions and quality. Controlling dimensions is critical to ensure proper box fit for pizzas, minimizing waste, and maintaining a positive customer experience. Understanding the processes, challenges, and tools used in this manufacturing process is vital for optimizing efficiency and maintaining product standards.

Dimension Control Processes

The process of manufacturing large pizza boxes typically begins with the preparation of raw materials. These materials, often cardboard or corrugated board, are carefully measured and cut to precise dimensions. Subsequent stages involve shaping and assembling the box components. The precision of these steps directly affects the final dimensions of the box.

Challenges in Maintaining Consistent Dimensions

Maintaining consistent dimensions across different batches of large pizza boxes presents several challenges. Variations in raw material quality, fluctuations in machinery settings, and human error can all contribute to inconsistencies. For example, variations in the moisture content of the cardboard can affect its dimensions. Environmental factors, such as temperature and humidity, can also impact the dimensions of the cardboard and the accuracy of the machinery.

Furthermore, the complexity of the manufacturing process itself, involving multiple steps and potentially different operators, adds to the challenge of maintaining consistent dimensions across large batches.

Role of Machinery and Tools

Sophisticated machinery plays a critical role in controlling dimensions during the manufacturing process. Automated cutting machines are often used to ensure precise cuts for the box components. Laser cutters and computer-aided design (CAD) software can further enhance accuracy and precision. These machines can be programmed with precise specifications for each box dimension. Furthermore, the quality of the machinery and its regular maintenance directly influence the dimensional accuracy of the final product.

Calibration of machinery is a crucial process for maintaining dimensional consistency.

Impact of Materials and Processes on Structural Integrity

The materials used and the manufacturing processes employed significantly affect the structural integrity of the large pizza boxes. The type of cardboard, its thickness, and the quality of the adhesives used in the assembly process all influence the box’s ability to withstand the weight of the pizza. For instance, a thinner cardboard with inadequate adhesive strength could lead to box collapse.

The dimensions of a large pizza box, often a crucial factor for proper fitting and storage, are surprisingly important. Finding a reliable pizza place in Edmond Oklahoma, like those listed on pizza places in edmond oklahoma , can significantly influence the choice of box size. Ultimately, knowing the standard dimensions of a large pizza box ensures your pizza arrives in perfect condition, whether you’re picking it up or having it delivered.

Optimizing the manufacturing process to minimize stress on the cardboard during handling and assembly is vital for maximizing structural integrity.

Production Process Flow Chart, Dimensions of a large pizza box

| Stage | Dimension Monitoring Point |

|---|---|

| Raw Material Inspection | Thickness, width, and length of cardboard sheets are measured and checked against specifications. |

| Cutting and Shaping | Automated cutting machines are calibrated and monitored to ensure precise cuts. |

| Assembly | Automated assembly lines are monitored for proper alignment and adherence to dimensions. Measurements are taken at key points of assembly to maintain consistency. |

| Quality Control | Random samples are taken at various stages to ensure dimensions conform to specifications. Specialized measuring tools are used for precise measurements. |

| Packaging | Boxes are measured and sorted according to dimensions before packaging to prevent errors in shipping and handling. |

Customer Experience and Usage

The customer experience with a large pizza is significantly influenced by the design and dimensions of the box. A well-designed box enhances the enjoyment of the pizza, while a poorly designed one can detract from the experience. Factors like ease of carrying, the pizza’s presentation, and the overall satisfaction directly relate to the box’s dimensions.Proper box dimensions contribute to a positive customer experience, facilitating easy handling and maintaining the pizza’s integrity.

Conversely, inadequate dimensions can lead to difficulties in carrying, potential spills, and a compromised presentation, impacting customer satisfaction.

Impact of Box Dimensions on Carrying and Handling

Box dimensions directly affect the customer’s ability to carry and handle a large pizza comfortably. A box that is too tall or wide can be cumbersome to maneuver, potentially leading to spills or dropping the pizza. Conversely, a box that is too small may not adequately protect the pizza, leading to damage during transport. The ideal box design allows for a secure grip and manageable weight distribution.

Effect of Variations in Box Dimensions on Usability and Perceived Value

Variations in box dimensions can significantly affect the usability and perceived value of a large pizza. A box that is too shallow might allow the pizza to shift or slide, leading to a less secure and aesthetically pleasing experience. Conversely, a box that is excessively deep could make it difficult to remove the pizza. Optimizing box dimensions ensures the pizza is presented well and protected during transport, enhancing the customer’s overall impression.

Common Customer Complaints Regarding Large Pizza Box Dimensions

Common customer feedback regarding large pizza box dimensions frequently centers around issues with handling and the pizza’s presentation. Customers often complain about boxes that are too heavy to carry, making them difficult to transport, or too flimsy, leading to damage or spills. Boxes that are too small for the pizza size may cause the pizza to shift or topple during transportation, resulting in a less-than-ideal presentation.

Customer Feedback Analysis

| Feedback Category | Frequency |

|---|---|

| Heavy and cumbersome to carry | High |

| Pizza shifting/toppling during transport | Medium |

| Box too small for pizza size | Medium |

| Box flimsy and prone to damage | Medium |

| Poor presentation of pizza | Low |

The table above summarizes customer feedback categories and their corresponding frequencies. This data demonstrates that issues with carrying and structural integrity of the box are most frequently reported.

Customer Scenario: Impact of Poor Box Dimensions

A customer orders a large pizza for delivery. The pizza box is excessively tall and narrow, making it awkward to carry. The customer struggles to grip the box securely, and the pizza shifts within the box. Upon arrival, the pizza is lopsided and the toppings are smeared. The customer is disappointed with the experience, feeling that the pizza’s quality was compromised by the poorly designed box.

This scenario exemplifies how poor box dimensions can negatively impact the customer experience, affecting not only the pizza’s presentation but also the customer’s overall satisfaction.

Environmental Considerations: Dimensions Of A Large Pizza Box

Minimizing the environmental footprint of large pizza boxes is crucial for sustainability. Careful consideration of materials, design, and manufacturing processes is essential to reduce waste and promote responsible consumption. This section explores the environmental impact of different pizza box components, highlighting the importance of sustainable choices.Choosing eco-friendly materials and designs directly impacts the overall environmental footprint of the pizza delivery system.

A comprehensive approach to box creation and usage, including responsible disposal practices, is vital for a positive environmental outcome.

Material Impact on the Environment

Different cardboard types and other materials used in large pizza boxes exhibit varying degrees of environmental impact. Recyclability is a key factor in assessing the overall sustainability of these materials. The manufacturing process, transportation, and eventual disposal all contribute to the environmental footprint.

- Cardboard types significantly influence the environmental impact. Recycled cardboard, derived from previously used paper products, often has a lower carbon footprint compared to virgin cardboard, which requires new raw materials and energy-intensive production processes. The quality of the recycled cardboard also affects its performance in the box-making process, including its strength and durability.

- The recyclability of a pizza box material is paramount. Cardboard, being a widely recyclable material, can be processed into new paper products, reducing the demand for virgin resources. Materials that are not easily recyclable or have a complex recycling process increase the environmental burden.

Sustainability of Large Pizza Box Designs

The design of large pizza boxes plays a role in their environmental impact. Efficient designs can minimize material waste, while poorly planned designs can lead to increased material consumption and disposal problems. Consideration of these aspects during the design phase is essential.

- Box designs that minimize material usage while maintaining structural integrity contribute to sustainability. Optimal box geometry and the use of lightweight materials, without sacrificing structural strength, can lead to reduced material waste.

- Box designs that are easy to recycle, such as those with minimal printing or easily separable components, facilitate proper waste management and resource recovery. Designs that incorporate interlocking flaps, for instance, can increase the ease of recycling.

Dimension Impact on Material Waste

The dimensions of large pizza boxes directly affect the amount of material used. Oversized or poorly proportioned boxes lead to unnecessary material consumption, increasing waste and the environmental footprint. Precise sizing is crucial.

- Excessive dimensions result in significant material waste. Optimizing box dimensions to precisely match the pizza size minimizes excess material, reducing waste during production and improving overall resource efficiency.

- Properly dimensioned boxes can significantly reduce material consumption, contributing to reduced environmental impact. Using appropriate templates and software tools for designing the box, coupled with careful measurements, minimizes waste and improves the cost-effectiveness of production.

Comparison of Materials and Environmental Footprint

A comparison of different pizza box materials reveals varying levels of environmental impact. Factors such as material sourcing, manufacturing processes, and recyclability influence the overall footprint. Reliable data sources, including life-cycle assessments, are essential for a comprehensive understanding.

- Cardboard, a common pizza box material, has a relatively lower environmental footprint compared to plastic or other materials. Its recyclability and biodegradability contribute to a positive environmental impact.

- The use of biodegradable or compostable materials in large pizza boxes is an evolving area. Research and development in this field are crucial to assess the practical implications and scalability of these materials.

Material Impact Table

| Material | Environmental Impact Score (1-10, 1 being lowest) | Recyclability (1-5, 1 being low) |

|---|---|---|

| Recycled Cardboard | 2 | 4 |

| Virgin Cardboard | 5 | 3 |

| Corrugated Cardboard | 3 | 4 |

| Plastic | 8 | 1 |

Wrap-Up

![How Big Is A Pizza Box? [By Brand] - Kitchen Seer Dimensions of a large pizza box](https://1upstudio.armadilloamarillo.com/wp-content/uploads/2025/04/Pizza-boxes-stack-isolated-on-white.jpg)

In conclusion, the dimensions of a large pizza box are far more intricate than they initially appear. From the initial design considerations to the final customer experience, numerous factors converge to create the perfect balance. This investigation has unveiled the hidden complexities behind the seemingly simple box, demonstrating the importance of careful consideration at each stage of the process.

Ultimately, the goal is not only to accommodate the pizza but also to ensure a satisfying experience for the consumer while minimizing environmental impact.

FAQ Compilation

What are the typical dimensions of a large pizza box in inches?

A standard large pizza box typically measures around 16 inches in length, 12 inches in width, and 2 inches in height.

How does the material of the box affect its volume?

Different cardboard thicknesses and types influence the volume. Thicker cardboard creates a more robust box, while thinner material might result in a smaller volume.

What are common customer complaints about large pizza box dimensions?

Some customers report issues with boxes being too small for their pizza, while others find them too large and unwieldy to carry. There can also be concerns about the box’s structural integrity.

What is the environmental impact of different pizza box materials?

Different cardboard types vary in their recyclability and environmental footprint. Recycled cardboard is generally more sustainable than virgin material.