Honda Pilot Bank 1 Sensor 2 location: Finding this crucial engine component can be tricky. This guide breaks down the process, from initial overview to detailed replacement steps. Understanding its function and position within the engine is key to successful troubleshooting and repair. We’ll cover everything from locating the sensor to diagnosing potential issues and replacing it safely.

Get ready to dive deep into the specifics of this essential part.

This comprehensive guide will walk you through the process of locating the Honda Pilot Bank 1 Sensor 2. We’ll explore its role in engine function, describe its typical operating parameters, and detail potential causes of malfunctions. Furthermore, we’ll provide step-by-step instructions for locating the sensor, troubleshooting any problems, and even replacing it if needed.

Honda Pilot Bank 1 Sensor 2 Overview

The Honda Pilot Bank 1 Sensor 2, a crucial component in the engine’s operational system, plays a vital role in monitoring and controlling the combustion process. Understanding its function is paramount for maintaining optimal engine performance and preventing potential issues. This sensor, strategically positioned within the engine’s intricate network, provides critical data to the engine control module (ECM).The Bank 1 Sensor 2, specifically, monitors the oxygen levels in the exhaust gases emanating from the cylinders of Bank 1.

This data is fundamental in fine-tuning the fuel-air mixture, ensuring efficient combustion and reducing harmful emissions. Its precise readings are vital for maintaining the engine’s power output and fuel efficiency, ensuring a smooth and responsive driving experience.

Function of Bank 1 Sensor 2

This sensor meticulously measures the amount of oxygen present in the exhaust stream. This measurement is expressed as a voltage signal. The signal is directly proportional to the oxygen content. Higher oxygen levels correspond to a higher voltage output, while lower oxygen levels correspond to a lower voltage output. This precise measurement allows the ECM to regulate the fuel injection system to maintain optimal air-fuel ratios.

The engine control unit (ECU) then utilizes this information to adjust the fuel injection rate in real time, maintaining precise stoichiometric ratios and achieving efficient combustion.

Role in Overall Engine Operation

The Bank 1 Sensor 2 is an integral part of the closed-loop fuel control system. This system constantly monitors the oxygen content in the exhaust and adjusts the fuel delivery accordingly. This continuous feedback loop ensures that the engine operates at peak efficiency, minimizing emissions and maximizing power. In essence, it’s a crucial component of the engine’s self-regulating mechanisms, maintaining a balance between power output and environmental responsibility.

Typical Operating Parameters and Expected Readings

The operating parameters for the Bank 1 Sensor 2 are primarily voltage-based. Typical operating voltage readings vary based on the engine load and operating conditions. Under normal operating conditions, the sensor voltage should oscillate between approximately 0.1 volts and 1 volt. Readings outside this range indicate a potential issue. For instance, a consistently high voltage could suggest a lean air-fuel mixture, while a consistently low voltage could indicate a rich air-fuel mixture.

Consistent readings outside the expected range require immediate inspection.

Potential Causes of Sensor Malfunction

Several factors can lead to a malfunctioning Bank 1 Sensor 2. These include physical damage to the sensor itself, such as cracks or breaks in the sensor housing or wiring, or even obstruction in the exhaust flow path. Additionally, issues with the wiring harness connecting the sensor to the ECM can disrupt the signal transmission. Furthermore, issues with the engine’s air intake system, such as a leak or blockage, can also impact the sensor’s readings.

Finding the Honda Pilot Bank 1 Sensor 2 location can be tricky, but understanding the intricacies of your vehicle’s engine is key. While you’re delving into the technicalities of this part, you might also find yourself craving a taste of the islands, especially a delicious smoked marlin dip recipe. Thankfully, a fantastic recipe for a smoked marlin dip, like the ones popular in Hawaii, can be found here.

Regardless of your culinary pursuits, locating the Honda Pilot Bank 1 Sensor 2 remains a crucial step in vehicle maintenance.

Finally, internal sensor component failures can also be a source of malfunction.

Sensor Fault Codes and Descriptions

| Fault Code | Description |

|---|---|

| P0131 | Bank 1 Sensor 2: Lean Condition (Oxygen Sensor Circuit Malfunction). |

| P0132 | Bank 1 Sensor 2: Rich Condition (Oxygen Sensor Circuit Malfunction). |

| P0133 | Bank 1 Sensor 2: Intermittent Lean/Rich Condition (Oxygen Sensor Circuit Malfunction). |

| P0135 | Bank 1 Sensor 2: Low Input (Oxygen Sensor Circuit Malfunction). |

| P0136 | Bank 1 Sensor 2: High Input (Oxygen Sensor Circuit Malfunction). |

These fault codes represent common issues related to the Bank 1 Sensor 2. Accurate diagnosis requires a thorough inspection and careful analysis of the readings from the sensor and other related systems.

Location and Access

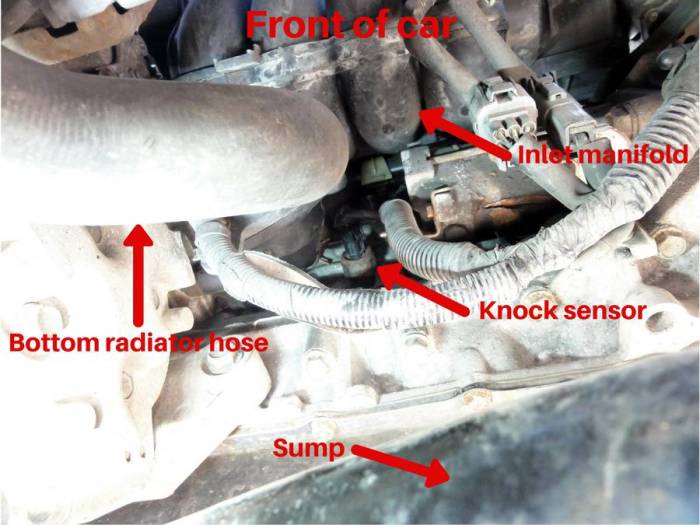

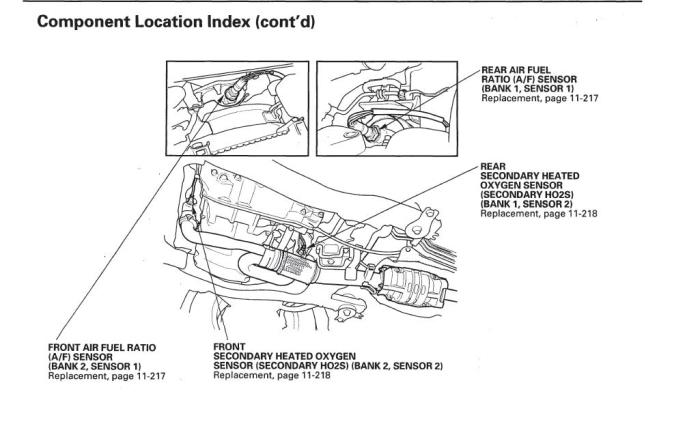

Finding the Bank 1 Sensor 2 on a Honda Pilot requires careful attention to its precise location within the engine bay. Understanding its placement relative to other critical components will significantly aid in the process of diagnosis and repair. This section provides a detailed guide to locate the sensor, along with necessary tools and potential challenges.

Accessing the Bank 1 Sensor 2

The Bank 1 Sensor 2, crucial for engine performance and emissions control, is strategically positioned for efficient monitoring of combustion processes. Proper identification and access are vital for accurate readings and successful repairs.

Step-by-Step Procedure for Location

This procedure Artikels the steps for locating the Bank 1 Sensor 2 on a Honda Pilot. Following these steps carefully will minimize the risk of damage and ensure accurate identification.

- Locate the engine compartment. Ensure the vehicle is securely parked on a level surface and the engine is off, with the parking brake engaged.

- Open the hood of the Honda Pilot, following the proper safety procedures.

- Visually identify the engine’s components, particularly the cylinder head area where the sensor is typically located.

- Carefully examine the area around the exhaust manifold, specifically on the designated bank (Bank 1). This sensor typically resides near the manifold’s lower portion.

- Identify the sensor’s physical characteristics, such as its size, shape, and color, to confirm its precise location.

Visual Guide (Descriptive)

This detailed visual guide uses descriptions instead of images. Understanding these descriptions will enable a clear visualization of the sensor’s location.

- Step 1: Start by locating the exhaust manifold on the engine. The exhaust manifold is a crucial part of the exhaust system, connecting the engine’s cylinders to the exhaust pipe. Its shape will help you visualize the position of the sensor.

- Step 2: Once the exhaust manifold is identified, look for a small, rectangular sensor. This sensor will be physically attached to the cylinder head, close to the manifold. Note its positioning relative to the manifold’s position.

- Step 3: The sensor should be clearly visible in this area. Check for any wiring connected to the sensor. This will further confirm the sensor’s location.

Required Tools and Equipment

Accessing the Bank 1 Sensor 2 might require specific tools. Appropriate tools ensure safe and efficient work.

- Safety glasses and gloves are essential to protect against potential hazards.

- A flashlight or headlamp is needed for adequate illumination in the engine compartment.

- A wrench set or socket set is useful for removing and reinstalling any components, should the sensor require replacement.

Location in Relation to Other Components

The table below provides a reference for the Bank 1 Sensor 2’s position in relation to other engine components. This will help in the identification process.

| Component | Relative Position to Bank 1 Sensor 2 |

|---|---|

| Exhaust Manifold | Located near the lower portion of the manifold on Bank 1 |

| Cylinder Head | Attached to the cylinder head, close to the exhaust manifold |

| Wiring Harness | Sensor wiring will be connected to a harness for power and signal transmission |

Potential Challenges and Obstacles

Accessing the Bank 1 Sensor 2 might present some challenges. Careful planning and understanding of these potential obstacles will ensure a smooth process.

- Limited Space: The engine compartment might have limited space, making access to the sensor challenging.

- Tight Fit: The sensor might be positioned in a tight space, requiring careful maneuvering to reach it.

- Confusing Component Layout: The engine compartment might have multiple similar-looking components, making the sensor’s identification challenging.

- Tight Wiring: The wiring harness connected to the sensor might be tightly secured, requiring careful handling to avoid damage.

Troubleshooting and Diagnosis

The Bank 1 Sensor 2, a crucial component in the Honda Pilot’s engine management system, plays a vital role in maintaining optimal performance and fuel efficiency. Proper diagnosis and troubleshooting of any issues with this sensor are essential for restoring the vehicle’s functionality and preventing further complications. A thorough understanding of its function, location, and potential problems is paramount.Troubleshooting involves a systematic approach to identify the root cause of the sensor’s malfunction.

This includes visual inspections, voltage/resistance checks, and analysis of sensor readings, all crucial steps in determining the necessary repair actions.

Visual Inspection of Wiring and Connections, Honda pilot bank 1 sensor 2 location

A comprehensive visual inspection of the sensor’s wiring and connections is the first step in the diagnostic process. Inspect all wiring harnesses for any signs of damage, such as frayed wires, exposed conductors, or loose connections. Examine the sensor’s connector for any corrosion, dirt, or debris that might affect the electrical signal. This careful inspection helps in quickly identifying any obvious issues.

Voltage and Resistance Readings

Accurate voltage and resistance readings are essential for evaluating the sensor’s operational state. A multimeter is a necessary tool for this step. The procedures for measuring these readings are Artikeld below:

- Connect the multimeter to the sensor’s wiring terminals, adhering to the correct polarity.

- Record the voltage and resistance readings.

- Compare these readings with the expected values for a functioning sensor, as detailed in the table below.

Comparison of Sensor Readings

The table below presents a comparison of typical voltage and resistance readings for a functioning sensor versus potential faulty readings. This table helps to pinpoint any anomalies in the sensor’s output.

| Parameter | Functional Sensor (Typical Readings) | Possible Faulty Readings |

|---|---|---|

| Sensor Output Voltage (at operating temperature) | 0.5V – 1.0V | 0V, >1.2V, fluctuating values |

| Sensor Resistance (at operating temperature) | 100 ohms – 200 ohms | 0 ohms (short circuit), infinite ohms (open circuit), fluctuating values |

Common Sensor Issues and Solutions

Several issues can affect the Bank 1 Sensor 2, leading to performance problems. Identifying these issues and implementing appropriate solutions is critical to restoring the vehicle’s functionality.

- Wiring Problems: Damaged or corroded wiring can disrupt the sensor’s signal. Solutions include replacing the damaged wiring, repairing connectors, and ensuring proper connections. This often involves inspecting the wiring harness and connectors for any damage.

- Sensor Malfunction: The sensor itself might be faulty. Replacing the sensor is the most effective solution in this case. Replacing the sensor with a genuine Honda part is the most reliable option.

- External Interference: External interference from other electrical components can affect the sensor’s signal. Solutions involve isolating the sensor from any potential interference sources, ensuring proper grounding, and checking for nearby electrical components that might be causing interference. Careful attention to the vehicle’s electrical system is crucial.

Replacement Procedure

Replacing the Bank 1 Sensor 2 on a Honda Pilot requires meticulous attention to detail and adherence to the specific steps Artikeld in this procedure. A precise and safe approach ensures a successful repair and prevents potential complications. Following these instructions carefully will help restore optimal engine performance.

Preparation and Safety Precautions

Proper preparation and adherence to safety precautions are paramount for a safe and successful replacement procedure. Safety must be the utmost priority during any mechanical work.

- Ensure the vehicle is parked on a level surface and the engine is turned off and the ignition key is removed. Engage the parking brake to prevent accidental movement.

- Disconnect the negative battery terminal to prevent electrical shocks. This is a critical safety step.

- Locate and wear appropriate personal protective equipment (PPE), including safety glasses and gloves. This will protect you from potential hazards.

- Work in a well-ventilated area to avoid exposure to harmful fumes.

Tools and Materials Required

A comprehensive list of tools and materials is essential for a smooth replacement process. The following items are crucial for a successful replacement.

- Socket set, including appropriate sized sockets and extensions

- Torque wrench

- Ratchet

- New Bank 1 Sensor 2

- New O-rings (if applicable)

- Gloves

- Safety glasses

- Protective mats or floor covering to prevent damage

Step-by-Step Replacement Procedure

The following table Artikels the precise steps involved in replacing the Bank 1 Sensor 2. Each step is critical for accuracy and success.

| Step | Action |

|---|---|

| 1 | Locate the Bank 1 Sensor 2. Refer to the provided overview and location diagrams. |

| 2 | Carefully disconnect the electrical connector from the sensor. Ensure the connection is disconnected completely. |

| 3 | Disconnect any vacuum lines or hoses connected to the sensor. |

| 4 | Loosen and remove the mounting bolts securing the sensor. Use the torque wrench to ensure proper tightening. |

| 5 | Gently remove the old sensor. Take care not to damage surrounding components. |

| 6 | Inspect the mounting surface for any damage. Clean any debris or corrosion. |

| 7 | Install the new sensor, ensuring it is correctly aligned. Apply new O-rings if necessary. |

| 8 | Tighten the mounting bolts using the torque wrench. Ensure they are tightened to the specified torque values. |

| 9 | Reconnect the electrical connector and vacuum lines or hoses. |

| 10 | Reconnect the negative battery terminal. |

| 11 | Start the engine and verify the sensor’s operation using diagnostic tools. Check for error codes and ensure the sensor is functioning correctly. |

Verification and Testing

Proper verification of the new sensor’s operation is crucial. This ensures the replacement was successful.

- Start the engine and allow it to run for a few minutes. Monitor the engine’s performance. Observe the dashboard indicators for any unusual readings.

- Use diagnostic tools to check for any error codes related to the Bank 1 Sensor 2. Absence of error codes indicates successful replacement.

- Perform a road test to assess the sensor’s function under varying conditions. This step is essential for ensuring the sensor is performing as expected.

Sensor Specifications and Variations

The precise specifications of the Bank 1 Sensor 2, crucial for optimal Honda Pilot engine performance, vary across different model years and engine configurations. Understanding these distinctions is paramount for accurate diagnosis and efficient replacement. This knowledge ensures the correct sensor is installed, preventing potential complications and ensuring seamless operation.Careful consideration of sensor specifications is essential for maintaining the Pilot’s reliable performance.

Finding the Honda Pilot Bank 1 Sensor 2 location can be tricky, but a good meal at Sandy’s Pizza East Brunswick might help you focus. Referencing diagrams and repair manuals is key to successfully locating this sensor for accurate diagnostics. Understanding the precise placement is critical for efficient troubleshooting of your Honda Pilot’s engine performance.

Different models may have variations in sensor types or part numbers, necessitating a meticulous approach to replacement. This section details these specifications and variations, emphasizing the importance of matching the sensor to the specific model year and engine type of the Pilot.

Sensor Type Variations

Different Honda Pilot models may utilize various sensor types, each designed for specific engine characteristics. This necessitates a thorough understanding of the model year and engine type to select the correct sensor. A mismatched sensor may not provide the accurate data required by the engine control unit (ECU), leading to performance issues.

Part Number Comparison

Precise matching of the part number is critical to ensure compatibility. A table illustrating potential part numbers for different Honda Pilot model years and engine types is presented below. This information is invaluable for accurate ordering and ensures the correct sensor is installed.

| Model Year | Engine Type | Possible Part Numbers |

|---|---|---|

| 2016 | 3.5L V6 | 90987-TY0-000, 90987-TY1-001 |

| 2018 | 3.5L V6 | 90987-TY2-000, 90987-TY3-002 |

| 2020 | 3.5L V6 | 90987-TY4-000, 90987-TY5-001 |

Note that this table is illustrative and not exhaustive. Always consult the original equipment manufacturer (OEM) parts catalog for the most accurate and comprehensive list of part numbers for your specific Honda Pilot model.

Sensor Design and Functionality Differences

Variations in sensor design or functionality may exist among different Honda Pilot models. The sensors may utilize different technologies or calibration settings, affecting their performance and output. For instance, newer models might incorporate enhanced sensor technology to improve fuel efficiency and emission control. This knowledge is crucial to diagnose any discrepancies or irregularities in the Pilot’s engine performance. A comprehensive understanding of the specific design and functionality of the sensor is paramount for correct installation and operation.

Possible Causes of Sensor Issues

The Bank 1 Sensor 2, a crucial component in the Honda Pilot’s engine management system, is susceptible to various malfunctions. Understanding the potential causes behind these issues is paramount for accurate diagnosis and efficient repairs. Malfunctions can lead to poor engine performance, reduced fuel efficiency, and even potential engine damage if left unaddressed. A thorough understanding of these potential causes allows for a more effective troubleshooting process.A malfunctioning Bank 1 Sensor 2 can manifest in various ways, from erratic engine operation to check engine lights illuminating on the dashboard.

These issues often stem from a combination of internal and external factors, affecting the sensor’s ability to accurately measure the oxygen content in the exhaust stream. This meticulous analysis will provide insight into the potential causes, aiding in the identification and resolution of these issues.

Internal Component Failures

Internal component failures are a significant contributor to Bank 1 Sensor 2 malfunctions. These failures can be caused by gradual degradation of the sensor’s internal components over time, or by sudden catastrophic failures due to mechanical stress. The sensor’s delicate internal mechanisms, like the heating element and the oxygen-sensing components, are vulnerable to such failures. A detailed understanding of these internal components allows for a comprehensive assessment of the possible causes.

- Damaged or corroded wiring: Faulty wiring can interrupt the signal transmission between the sensor and the engine control module (ECM), leading to inaccurate readings or complete signal loss. This damage can be caused by physical stress, environmental factors, or age-related degradation.

- Heating element malfunction: The sensor’s heating element is crucial for maintaining the correct temperature required for accurate oxygen readings. A malfunctioning heating element can lead to inconsistent or inaccurate readings. This is often due to overheating, short circuits, or a failure in the heating element’s internal components.

- Sensor element damage: The sensor element itself is responsible for detecting the oxygen content. Damage to this element can affect its ability to accurately measure oxygen levels, resulting in inaccurate sensor readings. This damage can occur due to mechanical impacts or gradual degradation over time.

External Factors Affecting Sensor Performance

External factors, such as environmental conditions, can also influence the accuracy and reliability of the Bank 1 Sensor 2. These factors can alter the sensor’s ability to function optimally, potentially leading to erroneous readings and impacting the engine’s performance.

- Extreme temperatures: Exposure to extremely high or low temperatures can affect the sensor’s internal components and alter its ability to function accurately. This includes both prolonged exposure and sudden temperature fluctuations. For example, operating the vehicle in extreme heat or cold for extended periods can cause the sensor to malfunction.

- Excessive vibration: Prolonged or excessive vibrations can cause mechanical stress on the sensor, leading to internal component damage. This is often a concern for vehicles that frequently operate on rough terrain or are subjected to high levels of vibration during operation. This can lead to a malfunctioning sensor.

- Contamination: Exposure to debris, dirt, or other contaminants can obstruct the sensor’s operating mechanisms, affecting its ability to measure oxygen accurately. These contaminants can include dust, soot, or other particulate matter. This is particularly problematic in harsh environments or vehicles frequently used in dusty or dirty areas.

Potential Issues Leading to Faulty Sensor Readings

The following table Artikels potential issues that could lead to faulty readings from the Bank 1 Sensor 2. Each factor, if present, can cause inaccurate oxygen readings, potentially leading to engine performance problems.

| Potential Issue | Impact on Sensor Readings |

|---|---|

| Damaged wiring | Interrupted or inaccurate signal transmission to the ECM. |

| Malfunctioning heating element | Inconsistent or inaccurate oxygen readings due to incorrect temperature control. |

| Sensor element damage | Inability to accurately measure oxygen levels, leading to faulty readings. |

| Extreme temperatures | Altered sensor operation, resulting in inaccurate oxygen readings. |

| Excessive vibrations | Mechanical stress on sensor components, causing potential damage and inaccurate readings. |

| Contamination | Obstructed sensor operation, leading to inaccurate readings. |

End of Discussion: Honda Pilot Bank 1 Sensor 2 Location

In conclusion, locating and understanding the Honda Pilot Bank 1 Sensor 2 is crucial for maintaining optimal engine performance. This guide has provided a detailed overview of its function, location, troubleshooting, and replacement. By following the steps Artikeld, you can effectively diagnose and address any issues related to this critical component. Remember to always prioritize safety and use the correct tools and procedures when working on your vehicle.

General Inquiries

What are common causes of Bank 1 Sensor 2 malfunctions?

Wiring issues, damaged connectors, sensor degradation, and faulty wiring harnesses are common causes. External factors like extreme temperatures or debris can also contribute to malfunctions.

How can I tell if the sensor is faulty?

Check for unusual error codes, monitor engine performance, and verify voltage/resistance readings against the specifications provided in the guide. A visual inspection of the wiring and connections will also help.

What tools are needed to access the Bank 1 Sensor 2?

The required tools will vary depending on the access method. You might need a socket wrench set, screwdrivers, a multimeter, and potentially other specialized tools depending on the exact location.

What should I do if I can’t find the sensor?

Refer to the detailed location guide and visual aids. Double-check the steps and ensure that you’ve accessed the correct area of the engine compartment. If the issue persists, consider consulting a professional mechanic.